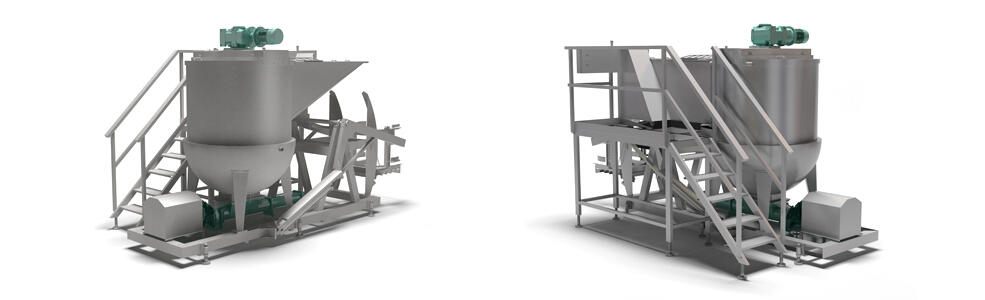

Crusher System

Designed for the efficient emptying and processing of cylindrical and conical open top drums of frozen fresh juice or concentrate.

Our Crusher System allows the efficient processing of frozen fresh juice or juice concentrate from open top drums by crushing and emptying the frozen product.

The contents of the drums are carefully crushed and melted, ensuring the quality of the final product and avoiding flavour alterations due to overheating.

The resulting flakes can optionally be melted with an additional steam melting system, which allows an easier and more efficient pumping of the product in liquid state for the further processing steps and avoids the formation of larger frozen blocks.

The drums approach the lifting station on a roller transporter and are pneumatically clamped, lifted and tilted in the highest position so that the frozen contents enters the collection hopper. The stainless-steel helical cutting blades chop the frozen product. The system includes a tank with a chamber at the bottom to melt the chopped product and prevent the formation of larger frozen blocks. The product is finally discharged by a screw pump.

Features:

PLC for process control

Pneumatic double lifting system

Purge system for condensed steam

Pneumatic active safety system

CIP spray cleaning system

Operator side platform with stainless steel non-slip steps

Magnetic safety sensors on the tank covers

Structure, security fence and elements in contact with the product made in stainless steel

Processing capacity:

Crushed and melted: 40 drums/h

Crushed and pumped: 60 drums/hType of drums: Open-top cylindrical and conical

Capacity of the drums: 200/250 l

Steam chamber connection: Female thread G 1 1/4".

CIP connection: Female thread G 3/4"

Pneumatic connection: Quick connector Ø10

Crusher motor power: 3 kW

Pump power: 11 kW

Weight: 2000 kg