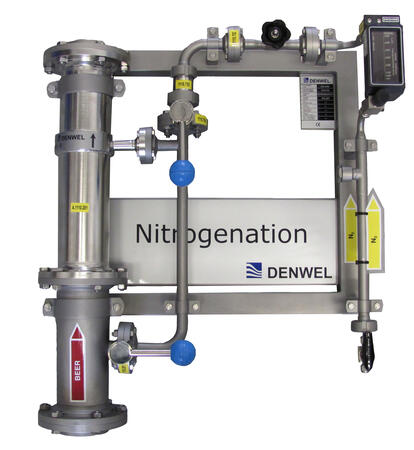

Inline nitrogenation

A manual unit designed for inline nitrogenation.

Improves foam stability

Microbubble size

Instant saturation

Efficient, hygienic design

N2 is injected into the beverage through the Bucher Denwel Injector, which splits the gas into microbubbles. The most efficient and instant saturation of N2 is achieved with only a minimal pressure drop, no gas loss and a fully hygienic design. No static mixer, sintered candle or recirculation tank is needed. Designed for CIP, no parts of the Injector need to be removed for sanitation.

The unit comes assembled on a compact frame and is tested so it can rapidly be put into operation. Proven components guarantee low maintenance and extended lifetime. The modular layout allows for easy integration into the plant and efficient combination with other process units.

Nitrogenation: up to 20 ppm (P & T dependent)

Pressure: operating 3 to 5 barg, 44 to 72 psig

Temperature: operating 0 to 5 °C, 32 to 40 °F

CIP: 3 to 5 barg, 44 to 72 psig; max. 90 °C, 200 °F

Connection: Tri-clamp; other connections upon request

Dimensions: from Height 0.8 m, 31.5”; Width 1.1m, 43,3”; Depth 0.2m, 6,5”

Weight: from 25 kg, 55 lb

Material: Stainless Steel 304, EPDM, PSU, PP

Frame: Mobile or Wall-mount